- Capacity : 2-35 t/1.4-24.5 MW

- Pressure ≤2.5MPa

- Coking waste heat flue gas

Coking plant

-

Brief introduction:

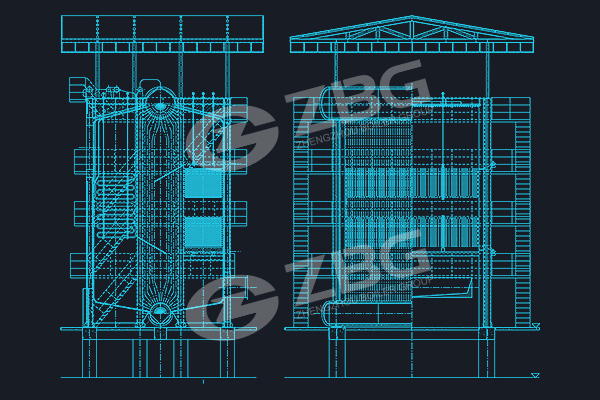

Coking plant produces large amounts of 550~900℃ coking waste gas during its production, to further utilize the waste heat we have developed the coking waste heat recovery boiler to improve energy utilization and protect environment.

-

Efficient recycle of waste gas

For further recycle of the waste gas, our company developed the boiler of supplemental combustion and the boiler without supplemental combustion. Complementary combustion boiler is equipped with automatic coke oven gas burner, coke oven gas fuel, firing with coking waste gas in boiler chamber to generate steam. Non-complementary combustion boiler, with new and vertical structure, can burn coking waste heat gas directly.

-

-

No leakage, safe operation

Hot and cold fluid completely separated, effectively prevent the leakage of water vapor system. At running-time, due to a large number of flushing scouring, even if the pipe is damaged, it will not cause the soft water of the cold side leak to the hot side, which ensures the safe operation of the system.

-

Anti-dust, corrosion resistance

Adjusting the ratio of heating surface at the heat pipe cold section, tube wall temperature will be higher than the dew point of the flue gas temperature or the maximum corrosion zones, effectively preventing corrosion caused by acid dew point and sulfur in the flue gas, extending the life of heat exchangers, and ensuring the heat exchange efficiency of the heat exchanger.