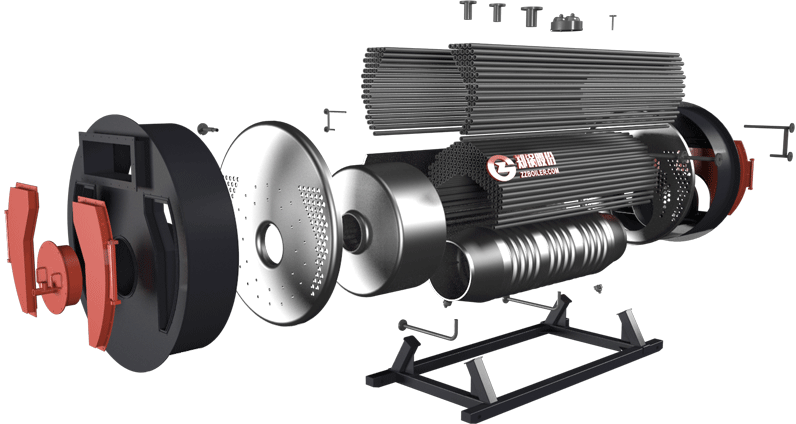

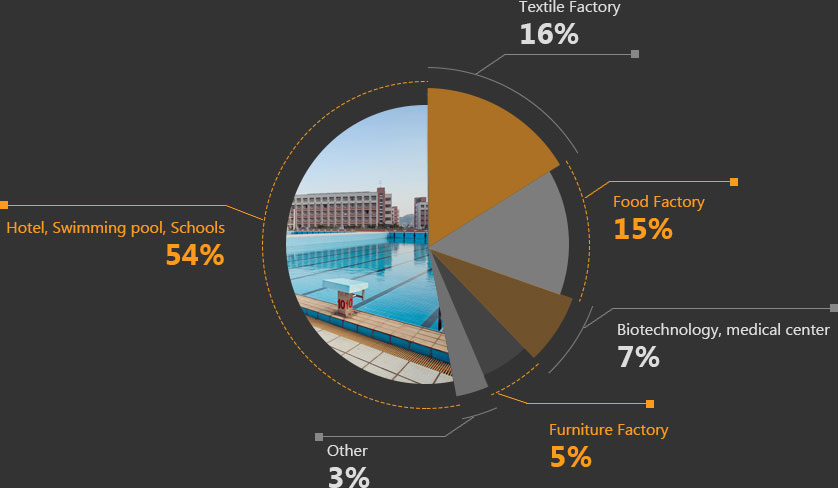

WNS series gas and oil fired boiler is the sub-project of high efficiency and eco-friendly boiler under the World Bank’s GEF Program. Each technical indicator of boiler parts can be advanced in world. As a kind of fast-assembly installation boiler, it consists of boiler proper, interconnecting flue, burner, steam & water system, economizer, etc. It can also be regarded as fire tube boiler, packaged boiler, and eco-friendly boiler.