18 TPH Rubber Wood fired Boiler

2022-09-12 10:10:52From the perspective of using rubberwood as fuel, it is apparent that rubberwood is a promising candidate as an alternative renewable energy source. In addition, the conversion technologies such as combustion, pyrolysisand gasification have been used to generate energy from rubberwood biomass. In fact, Lim et al. identified that the energy content of rubberwood can be as high as about 68.61 million gigajoules (GJ) per year or 40.04 GJ per hectare per year. Based on this estimation of energy content, Table 3 summarizes the potential energy production that could be realized from the rubberwood waste available for fuel.

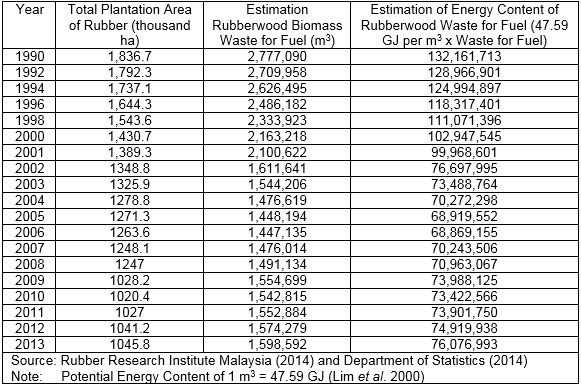

Table 1. Estimation of Energy Generation from Rubberwood Waste as Fuel

As shown in Table 1, the energy supply from rubberwood waste reduced significantly owing to the reduction in rubber cultivation area, which consequently decreased the available amount of rubberwood biomass.

In Thailand, there is a furniture factory that produces rubber wood. Every year, a large amount of rubber wood is used for furniture production. Due to poor production management, the factory cannot make ends meet. Coincidentally, ZBG company inspected the rubber wood production line in Thailand, and the head of the factory invited ZBG engineers to visit and guide.

In the factory, ZBG engineers found that the boilers used for drying wood on the production line were coal-fired boilers, which were expensive, and the bark and other wastes generated in the wood production process were disposed of at a low price to the plywood factory. This invisibly increases a lot of running costs.

18 TPH Rubber Wood fired Boiler

| 1 | device name | boiler |

| 2 | Model Specifications | SZL18-1.25-S |

| 3 | Arrangement location type | Double drum vertical type |

| 4 | Rated steam temperature | 193℃ |

| 5 | Rated evaporation | 18T |

| 6 | Rated feed water temperature | 105℃ |

| 7 | design fuel | biomass fuel |

| 8 | preset pressure | 1.25MPa |

| 9 | Design Thermal Efficiency | 81.7% |

| 10 | Hydrostatic test pressure | 1.6MPa |

| 11 | Heating area of grate | 20.8m2 |

| 12 | Radiant heating area | 59.95m2 |

| 13 | Convective heating area | 335.2m2 |

| 14 | Economizer heating area | 295m2 |

| 15 | Heating area of air preheater | 123.3m2 |

| 16 | Body water volume | 40m3 |

| 17 | exhaust temperature | 130℃ |

| 18 | Boiler gross weight | 127.645t |

| 19 | Dimensions after installation | 15800*4600*8700 |

Rubber Wood Fired Boiler Manufacturer

ZBG is a is growing as a global leader in boiler with its HQ and R&D center, and global sales network in more than 30 countries around the world. The biomass fired boilers are designed to burn rubber wood, bagasse, rice husk, straw, palm kernel shell, palm fiber, etc. Our rubber wood biomass fired boilers are selling well in Thailand.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.