- Capacity : 20-280 t/ 14-196 MW

- Pressure ≤5.29MPa

- Biomass,Rice Husk,Palm Kernel

Power Plant,Central Heating,City Heating

-

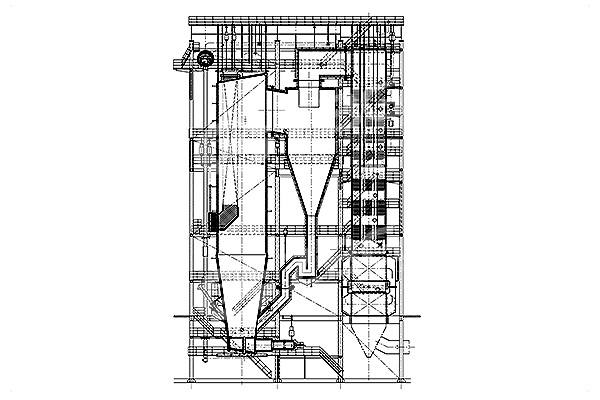

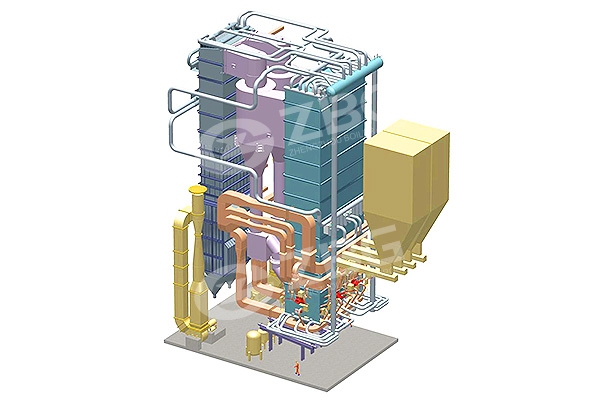

Brief introduction:

Biomass fired CFB boiler adopts patented technology membrane water-cooling wall structure, improved fuel crusher and screening system, combustion and heating efficiency is greatly improved. The boiler can burn both biomass fuel and coal.

-

Large furnace, low fuel costs

CFB biomass boiler have large combustion space and enough height to make sure the fuel have the sufficient time to burn in the furnace, meanwhile the adequate and stratified secondary air is deployed to fit in with the concentrated of volatile, so that guarantees the fuel and air are fully mixed to burn out in the furnace.

-

-

High combustion efficiency, cost savings

a. The suspension furnace equipped with the water-cooled wall and the inlet of separator is water-cooled flue duct make it less heat-releasing and boiler-efficiency improvement.

b. The separator and the center tube of loopback materials device have applied the technological improvements for low resistance, high separation efficiency, which ensure high combustion efficiency and low burn ash residual calorific value, savings cost.

-

Air preheater, avoiding corrosion

The air preheater use of a multi-tube box arrangement and low-temperature section use of corrosion-resistant steel to avoid the corrosion the parts by low temperature cause to replace the whole.

- Production line custom service

We have a professional and strong technical team that can provide you with system and production line customization service.