Coal Fired Boiler

2017-09-18 14:32:42

Coal boilers are commonly used to heat water and create steam for energy production and power generation. Coal-fired boiler efficiency can often provide lower operating costs in comparison to other fossil fuels – almost 75% less than oil or natural gas. Coal, when properly handled and combusted, is one of the cleanest fossil fuels available today. ZBG coal fired boiler capacity ranges from 2-410 tons per hour, which can meet the different needs of customers with advantages such as high efficiency, energy conservation, lower emission, wide coal adaptability, reliable performance.

ZBG coal fired boiler

Coal fired boilers produced by ZBG mainly include DZL coal fired boiler, SZL assembly coal fired boiler, coal fired CFB boiler, coal fired corner tube boiler, etc.

- DZL coal fired boiler

Capacity:2-10 tons. ZBG DZL coal fired boiler is independently by our company as the fourth generation horizontal water tube and fire tube package chain grate boiler. This boiler is equipped with compact structure, less floor space, quick and easy shipping & installation, highly efficient and reliable operation, conducive to low-quality coal combustion.

View details >>

-

- SZL assembly coal fired boiler

Capacity:6-25 tons. SZL assembly coal fired boilers with high efficiency, strong overload capacity and various fuel adaptability (biomass pallet or coal), compact and convenient installation, membrane water cooling wall structure, are well known as the best design among contemporary domestic similar products and have reached the world's advanced level.

View details >>

- Coal fired CFB boiler

Capacity:10-410 tons. ZBG coal fired boilers can be divided into external CFB coal fired boiler, inner CFB coal fired boiler, CFB coal fired power plant boiler, and our coal fired CFB boiler is listed as the NO. 1 among high efficient boilers in the “Energy Efficient Boilers Promotion Directory”, published by National Development and Reform Commission.

View details >>

- Coal fired corner tube boiler

Capacity:10-160 tons. Corner tube coal fired boiler adopts GEF program's technology. Based on the domestic and foreign technical research, according to the technical development characteristics and market demand of chain grate, we carried out independent innovative design so as to produce the high-capacity energy-saving chain grate boilers with advantages of reliable water cycling, efficient burning and low pollution.

View details >>

Coal fired boiler projects

-

280 Tons coal fired CFB in Inner Mongolia

280 Tons coal fired CFB in Inner Mongolia -

80 Tons coal fired Corner Tube Boilers

80 Tons coal fired Corner Tube Boilers -

Two sets coal fired boiler in Kazakhstan

Two sets coal fired boiler in Kazakhstan -

20 tons coal fired boiler for paper industry

20 tons coal fired boiler for paper industry

How to calculate coal boiler efficiency View details

One boiler’s actual efficiency depends its brand, burner, auxiliaries, installation, operator, fuel, etc. There are two method to measure the boiler efficiency, direct method and indirect method.

- A. Direct method

-

Boiler efficiency =Q*(Hg-Hf)/q*GCV *100 Q =Total steam flow Hg= Enthalpy of saturated steam in k cal/kg Hf =Enthalpy of feed water in kcal/kg q= quantity of fuel use in kg/hr GCV =gross calorific value in Kcal/kg.

- B. Indirect method

-

We need a following parameter like :1.Ultimate analysis of fuel ; 2.percentage of O2 or CO2 at flue gas; 3.flue gas temperature at outlet; 4.temperature and humidity of air; 5.GCV of flue in Kcal/kg; 6.ash percentage in combustible fue; 7.GCV of ash in Kcal/kg.

ZBG strength

Our products widely applies in manufacturing industry (chemical, coking, paper-making, food processing, etc.), thermal power plant, building material and other industry applications. no matter what industry you are engaged in, ZBG will be able to help you.

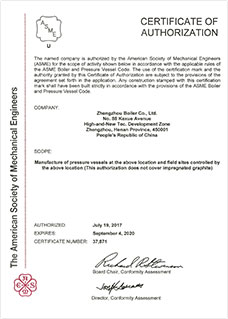

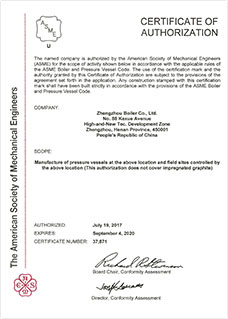

ZBG has American Society of Mechanical Engineers Certification (ASME U and ASME S Certifications), Russia, Belarus and Kazakhstan Customs Union(CU-TR Certification), Malaysia DOSH Certification and other international trade permits. We are committed to providing timely, rapid, and efficient services for each of our customers. Our service staffs are always online to solve your questions, any problem, just contact us!

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.