- Capacity : 1-20Ton/1.4-14MW

- Pressure ≤1.6MPa

- Natural Gas,Biogas,Light Oil,Diesel Oil

Textile plant,Heating Supply,Hotel,

Food & Beverage,Garment Manufacturing

-

Brief introduction:

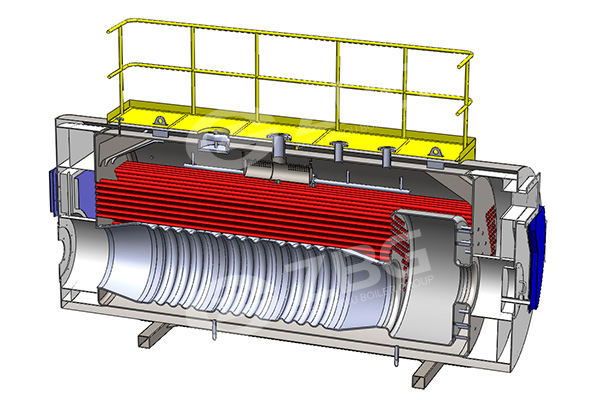

WNS series gas and oil fired boiler is the sub-project of high efficiency (up to 95% thermal efficiency) and eco-friendly boiler under the World Bank’s GEF Program. Each technical indicator of boiler parts can be advanced in world. This is a kind of fast-assembly installation boiler which consists of boiler proper, interconnecting flue, burner, steam & water system, economizer, etc.

-

High thermal efficiency and lower cost

a. Adopts advanced corrugated furnace and the smoke tube adopts thread structure to increase heat transfer area and heat transfer effectiveness, boiler thermal efficiency.

b. Tail with flue gas condensing recovery device to control the exhaust temperature effectively, boiler thermal efficiency;

c. Adopts internationally renowned brand burner (BALTUR, WEISHAUPT, RIELLO) and water supply with continuous electric adjustment to achieve high thermal efficiency.

-

-

High reliability, low maintenance cost

The smoke room of the boiler adopts water-cooled wet-back structure with butt weld , 100% water jacket fire overall design and high temperature flue gas is water space package, which is a good choice to solve the smoke room cooling and sealing. This design avoids the frequent maintenance work of the front and rear smoke boxes, and greatly reduces the boiler accident and maintenance workload to make the boiler run more secure and reliable.

-

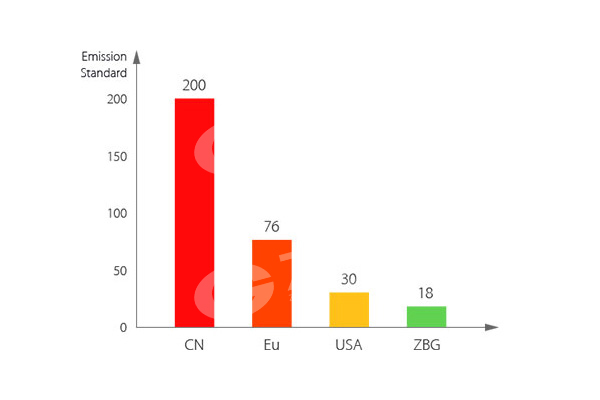

Lower NOx Emission

a. It adopts three pass structure, hot combustion gases pass through long, small-diameter tubes three times, absorbing heat as much as possible;

b. The large capacity combustion chamber (furnace) design ensures the fuel fully burned, and the smoke spread evenly to the NOX emissions to 35-200mg / m³, clean and environmentally friendly.

- Short installation period, save space

The use of quick-loading structure and the whole boiler design in a very strong steel base to make installation and transportation easily, save the occupied space of the boiler room.