Industrial Coal Fired Boiler

2016-03-09 10:53:39Coal plays a vital role in power generation worldwide, and for a long time the coal fired boilers are used in various fields for supplying heat, hot water, steam and electricity. ZG Group provides its clients with the support and expertise necessary to design, fabricate and install complete coal fired boiler systems. Various Coal Fired Boiler designs are suitable for applications to produce high pressure steam or hot water in ranges from 2 ton/hr to 280 ton/hr output from 1.0MPa up to 9.8MPa.

According to boiler firing way, coal fired boilers are simply classified into chain grate boiler and circulating fluidized bed boiler.

Coal Fired Chain Grate Boiler

Coal fired chain grate stokers have gravity feeding and burn fuel in a quiescent state. The fuel burns substantially on the grate, with only the volatile burning in suspension. Burning rates are low and burning is slow. The grate and the furnace are larger. As there is no agitation of the fuel bed to expose more surface, the ash in the fuel has to be low (<15%).

Coal fired chain grate stokers have gravity feeding and burn fuel in a quiescent state. The fuel burns substantially on the grate, with only the volatile burning in suspension. Burning rates are low and burning is slow. The grate and the furnace are larger. As there is no agitation of the fuel bed to expose more surface, the ash in the fuel has to be low (<15%).

Coal fuel requirement for chain grate boiler:

Particle size: 6~30mm

Water content: ≤12%

Ash content: ≤30%

Characteristic of char residue: ≤5

The chain grate boiler can be divided into packaged chain grate boiler, assembled chain grate boiler and field-assembled chain grate boiler. DZL series is a typical packaged boiler, single drum, water-fire tube boiler. The capacity is small from 2 ton - 10 ton easy to transport and install. SZL and SHL series are assembled water tube boilers with larger capacity 6 - 35ton/hr. As for the field-assembled coal fired boilers are usually used in captive power plant for electricity.

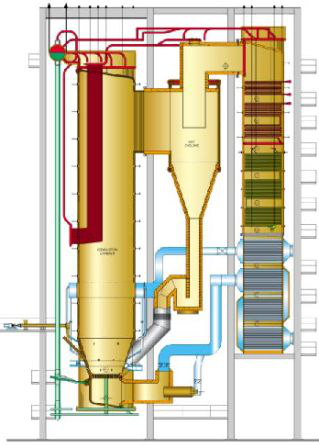

Coal Fired Circulating Fluidized Bed Boiler

Circulating Fluidized Bed Combustion(CFBC) is a new clean coal combustion technology, coal fuels can be fully burning with low emissions. The CFBC boilers also adopt coal and biomass co-firing, efficient and low cost.

Circulating Fluidized Bed Combustion(CFBC) is a new clean coal combustion technology, coal fuels can be fully burning with low emissions. The CFBC boilers also adopt coal and biomass co-firing, efficient and low cost.

It can burn a wide range of coal fuel, even bad grade coal that chain grate type boiler cannot burn, like coal gangue, chain grate slag, blast furnace gas slag, etc.

Coal fired circulating fluidized bed combustion boilers employ ash for cooling the bed, together with staged combustion, to contain the bed temperature and produce lower emission. The limestone and fresh fuel are added to the bed, which is composed of inert material or coal ash. The residence times are higher and velocities of fluidizing air are also more, making the boilers very tall and slender. And compared with the BFBC boilers, the carbon burn-up and desulfurization efficiency are better, load dynamics are superior, and reliability is higher in the CFBC boilers. Coal fired CFB boiler is seen as a potential utility boiler, both in terms of efficiency and capacity. May utility boilers are based on the CFB principle.

Reforming of Coal Fired Boiler to Biomass Fired Boiler

Some countries and regions have higher requirement for environment protection. Biomass as a clean and renewable fuel is becoming popular. Biomass fired boilers have high combustion efficiency up to 90% and very low CO2, NOx Emission. Co-firing of coal and biomass takes up a large market in electricity and heating. No matter the chain grate type boiler or CFBC type boiler can co-firing of coal and biomass, and it is fairly easy for enterprises to reform the coal fired boiler into biomass fired boiler.

Nowadays people are seeking for more efficient and clean energy, while coal fuel, for its cheap cost though high pollution, is still and going to be the main fossil fuel for a long time. The challenge is how to harness coal's energy more cleanly. With the ever-developing technology, boiler engineers are devoted to innovating boiler combustion systems to fully take advantage of coal fuel, so that the coal boiler efficiency is improved and the pollutant is reduced significantly.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.