Water Treatment in Industrial Boiler Operation

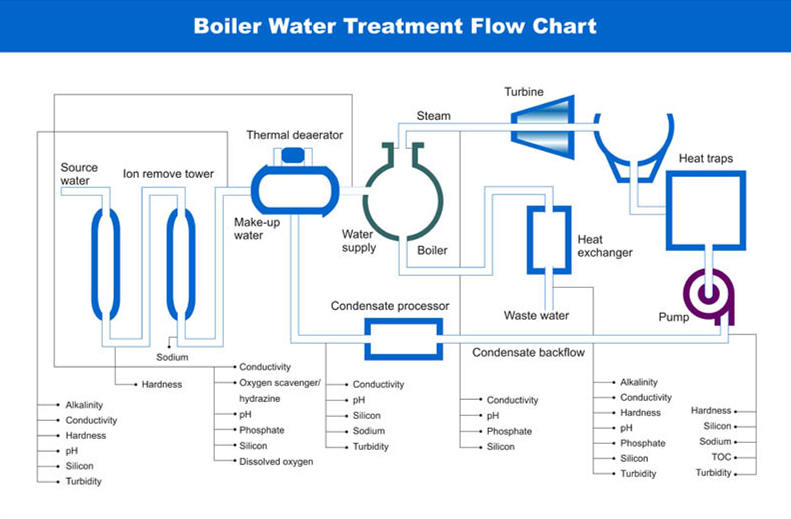

2016-03-09 10:45:39Water is the essential heart of every industrial boiler operation, proper treatment for feed water, make-up water is critical to achieve efficiency, cost savings and long term equipment life of the boiler. Poor or no water treatment results in sediment or scale forming that will lead to poor heat transfer, overheated and damaged boiler tubes and even boiler failures.

Boiler water treatment solutions

Water quality requirements and treatment technologies for boiler water depend primarily of the boiler type and operating pressure. These can vary widely, from simple soft water for low pressure boilers to near ultrapure water for critical boilers or nuclear power steam generators.

Demineralization – removes nearly all of the ions present in water, common with high pressure steam applications and pure water requirements.

Deionization – involves the process of passing water through an ion exchange to remove ions, salts and minerals.

Dealkalization – another form of ion exchange, used to reduce the corrosive carbon dioxide in boiler steam and condensate.

Reverse osmosis filtration – system membranes remove solids, dissolved minerals, organics, and other particles to produce high quality water.

Condensate polishers – used to filter water condensed from steam and remove or exchange ions in order to maintain condensate purity and prevent acidity that can cause corrosion.

In addition, cooling water also needs water treatment. Most process industries require cooling water for various applications around the plant. The operation of cooling water structure entails continuing costs for improved reliability and performance. Major problems include scaling, corrosion, fouling and bio-fouling. Without the use of effective processes and treatment to control microbiological growth, employees and the community may be exposed to health risks. Water treatments for use in cooling towers and both open and closed cooling water systems are applicable for hard and soft water conditions, inhibiting scale and corrosion and anti-foulants.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.