- Capacity : 20-400 t/ 14-280 MW

- Pressure ≤9.81MPa

- Coal, Biomass, Co-firing

Chemical Industry, Steel Industry,

Heating Industry

-

Brief introduction:

Drawing upon its extensive technical expertise and operating experience, ZBG developed the DHX series Circulating Fluidized Bed Steam Boiler, which is the good choice for power plant, heating company, and other industries seeking economy, reliability and flexibility.

-

High combustion efficiency

a. Due to the intense mass and heat exchange in the fluidized bed, unburned coal particles can increase the residence time in the furnace by multiple cycles, which is very beneficial to the fuel burnout.

b. Bell-covered style air cap, has features like low resistance, anti-back ash flow, falling of preventing, guaranteeing the boiler combustion efficiency.

-

-

Low pollution emissions

DHX-type circulating fluidized bed boiler in the appropriate calcium and sulfur ratio and limestone particle size, can be up to 80% - 90% of the desulfurization rate. Meanwhile, due to the lower combustion temperature, the use of graded air, which make the type of boiler combustion generated nitrogen oxides are also much lower than the pulverized coal furnace, so their sulfur dioxide and nitrogen oxides emissions are low.

-

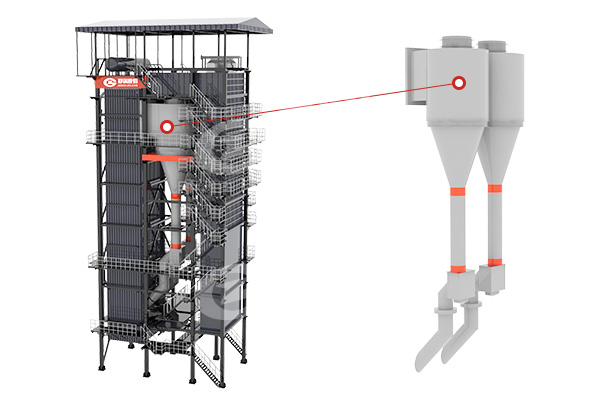

Parallel cyclone separator, good fuel separation

Furnace exit equipped with parallel high temperature cyclone separator makes the machine run stably and have a high rate of separation.

- Long working life

Wear-resisting device is equipped in the both of water-cooling wall tube and smoke stack tube to guarantee the working life of the heating surface.