- Capacity : 6-25 t/4.2-17.5MW

- Pressure ≤2.5MPa

- Bituminous Coal, Lignite Coal

Food Industry, Heating Supply

-

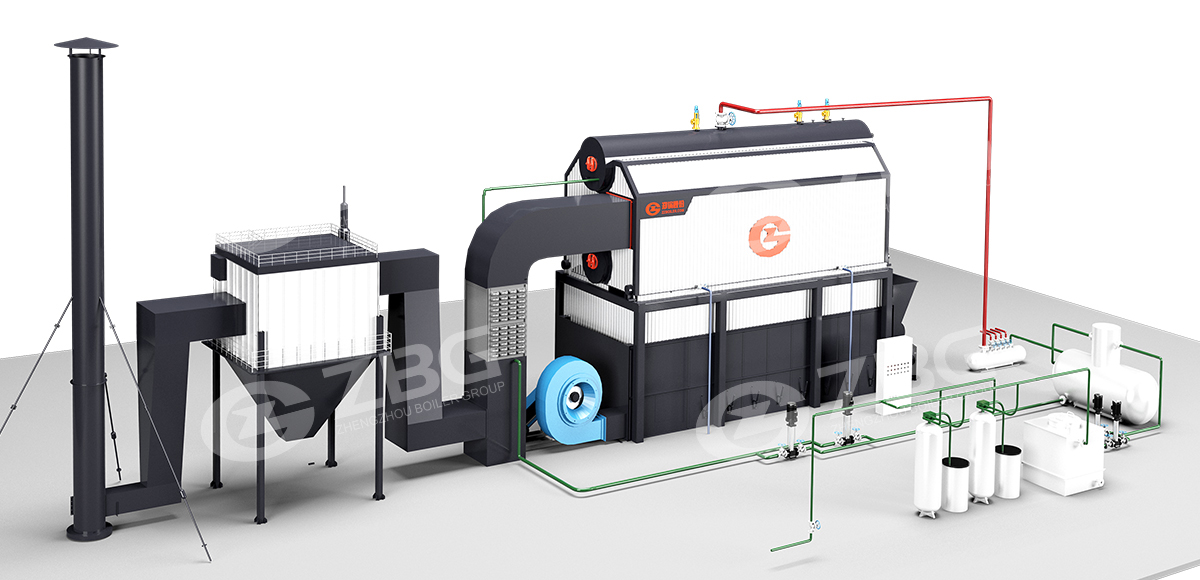

Brief introduction:

Water tube boilers are designed for larger, high-pressure, and superheated steam applications. SZL series coal fired chain grate boiler is a good example. Membrane water cooling wall structure in combustion chamber, good sealing to prevent heat loss.

-

Lower fuel costs

More combustion heat was being transferred into the boiler water. Combustion chamber airtightness and thermal conductivity directly influence thermal efficiency as well as boiler economical benefits. Because each 40°F reduction in the boiler flue gas temperature results in a 1% boiler-efficiency improvement. Fuel costs have decreased by approximately 4%.

-

-

Available to burn low grade fuel

a. Longer Fuel Combustion Period. Front arch is higher and shorter than rear arch, 45° angle between the two arches, which can extend the time of flue gas combustion time, and enhance thermal transferring efficiency.

b. It can burn low calorific value coal such as brown coal, lean coal, and flue coal.

-

The overload ability strengthened

The length of the front and back shaft is longer than the other ones, which prolongs the time of fuel combustion in the furnace and lower the carbon content in the furnace slag. Thus, the overload ability of the boiler is strengthened with the increased effect area of furnace grate.

- Burning effect is good

Wind is feed from both sides of the boiler. There are six independent air chambers, each of them has independent air adjustment device which can respectively adjust the air volume so as to achieve the best combustion effect.