-

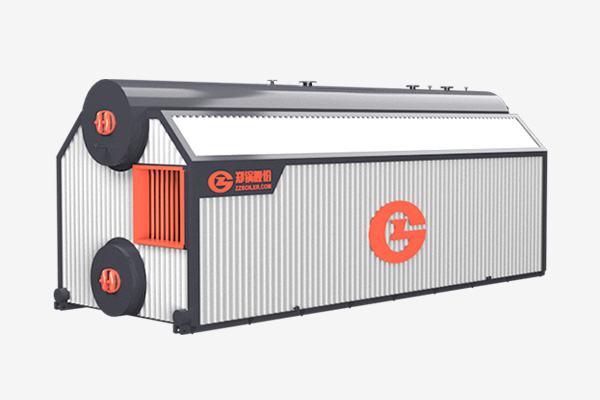

Textile is a multi - scale processing technique for a fiber or fiber aggregate. Whether it is dyeing, drying, sizing, printing and dyeing can not be separated from the support and coordination of steam boiler.

Get Tailored SolutionsProduct Center

As the textile industry is a relatively large industrial category, its consumption of fuel is greater, so it is the first choice for textile manufacturers to choose low fuel cost boiler.

The textile plant steam boiler provides heat for the dyeing and drying of yard goods. The fuels used for the production of thermal energy in general are diesel oil, heavy oil, LPG, coal, natural gas and solid fuels such as palm oil shell, rice husk and other biomass fuels. If the spinning plant just produces raw yarn in a cotton spinning system and does not dye of fix the produced yarn, the fuel will be used to provide steam for the humidification system in the cold seasons for preheating the fibers before spinning them together.