Boiler In Rice Mill

Rice is the second most important crop in the world and a rice industry is one of the most energy consuming industries. The rice milling industry can use rice husk as fuel; the rice husk boiler generates steam for the industry’s steam and electricity needs.

The rice husk (or hull) is the outermost layer of the paddy grain that is separated from the rice grains during the milling process. Around 20% of paddy weight is husk and rice production in Asia produces about 770 million tons of husk annually. Long before, rice husk was largely considered as a waste product that was often burned or dumped on landfills, but today it is increasingly used as biomass to fuel or co-fuel boiler or power plant. In rice mills, the rice husk firing boilers are providing steam for rice processing, or even driving force for power generation.

It is reported that one tonne of paddy produces 200 kg of husk, of which at least 180 kg could be recovered to be used as fuel. The heat value of husk was about 5 kWh/kg. 180 kg husk at an over all efficiency of 70 % in co-generation plant can supply 437.5 kWh energy. In a ratio 1: 9 between shaft power and process steam about 44 kWh mechanical energy that is much more than what is needed for milling, and sufficient heat energy would be available to produce parboiled rice. The rice husk biomass boilers in rice industry not only solve the problem of husk waste treatment, also reduce factory's fuel cost.

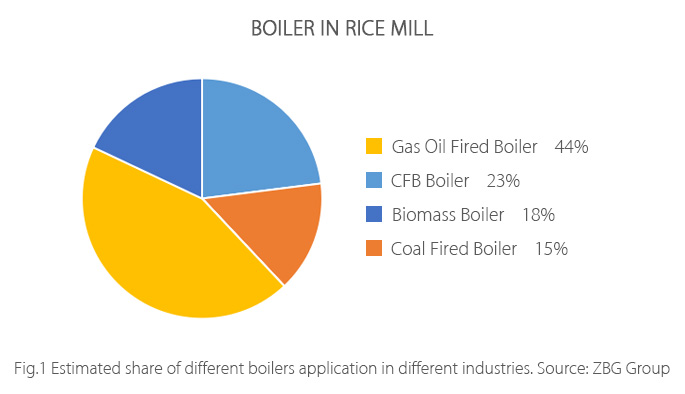

Which type of boilers apply to this industry?

-

SZL Series Biomass Chain Grate Boiler

SZL series is Bi-drum biomass steam/hot water boiler, water tube type boiler, membrane water cooling wall, high efficiency and energy saving....

Request a Quotation Chat online -

Rice Husk/ Straw Biomass Power Plant Boiler

Biomass power plant boilers can burn rice husk, rice straw or other biomass pellet to generate electricity for thermal power plant. ZBG provides 10 - ...

Request a Quotation Chat online -

DHL Corner Tube Biomass Fired Boiler

ZBG manufactures biomass power plant boiler burning bagasse, distillers grains, biomass pellet used in sugar industry, food processing, utility, etc....

Request a Quotation Chat online -

Biomass Fired CFB Boiler

As a leading biomass boiler manufacturer, we provide 10-280 ton energy saving biomass CFB boiler, which can burn rice husk, straw, bagasse, wood pelle...

Request a Quotation Chat online

Boiler In Rice Mill Projects

- >>Previous: Sugar Mill Steam Boiler

- >>Next: High-Strength Gypsum Production Line